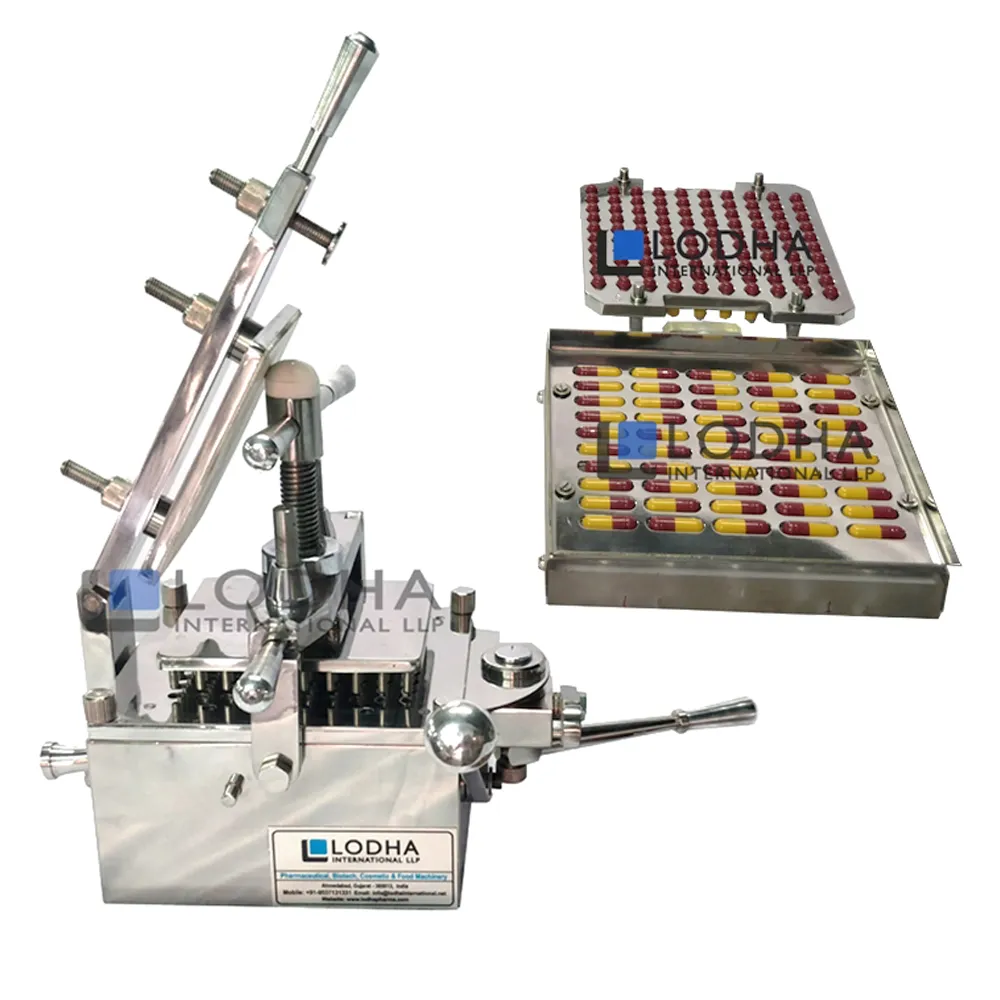

100 Holes Capsule Filling Machine

100 Holes Capsule Filling Machine is small bench top model suitable for R&D batch productions. Machine is having 100 holes with 10 x 10 combinations made in stainless steel constructions meeting cGMP requirements. Machine can fill size 00 to size 5 capsules with help of interchangeable parts and different machine model. Machine designed in such a way that it can be easily dismantle for cleaning operations. Though all the operations are manual, the machine calls for precision machined components and assembled with highly skilled personnel. Machine having wide usage in R&D laboratories, Research Institutions, Herbal & Nutraceutical preparations, Unani & Ayurvedic medicines etc.

Synonyms:

Laboratory Capsule Filler, Hand Held Capsule Filler, Mini Capsule Filler, Nutraceutical Capsule Filler, Small Capsule Filler

Application:

Filling Capsules with powder, pellets & granules

Usage:

Laboratory, Pharmaceutical, Nutritional, Biotech, Health Supplement, Food Product & Cosmetics

Suitability:

Hard Gelatin, HPMC & Veg Capsules in 00, 0, 1, 2, 3, 4 & 5 sizes

Versions:

Complete Stainless Steel GMP Model

Process Operation:

- Fill empty capsules onto the loading tray and place tray onto the machine. Check the front knob it should be turned right side.

- Pull locking lever forward. Push down long handle which will lifts the caps off all the bodies. Set aside the tray containing all the caps.

- Push locking lever back, by which capsule bodies will drop down and become level with filling surface.

- Place powder tray on filler: keeps powder from spilling

- Pour & spread the pre-measured powder. Move extra powder onto powder tray's shelf. Lower tamper and lock

- Turn handle to compress powder: this allows you to fill more powder in each capsule.

- Raise tamper & spread extra powder from shelf into capsules: ensures uniform fill weights.

- Return the tray containing caps to filler. Turn front knob to the left and lower locking plate. Engage lock for locking plate.

- Hold tamper handle and push down on long handle. Bodies are pushed up into caps: all the capsules are now locked in one step.

- Disengage lock for locking plate. Lift locking plate and turn front knob to the right.

- Push down long handle and remove tray of completed capsules.

- Capsules are filled now. You can turn tray and all the capsules will get out from the tray.

Technical Specification:

| Model No. | LI-CFM 100 |

|---|---|

| Production Output | Up to 2500 capsules per hour |

| Capsule Combinations | Size 00, 0, 1 & 2 in single machine model with the help of extra size change parts Size – 3 and Size – 4 in another machine model with help of any one size extra parts Size – 5 in single machine model |

| Sequence of holes | 10 x 10 = 100 |

| Loading Tray | One (With basic machine model) |

| Overall Dimension | 350 mm (L) x 265 mm (W) x 380 mm (H) approx. |

| Net Weight | 22 Kgs. Approx. |

| Gross Weight | 28 Kgs. approx. |

Countries We Export to

United States | Canada | Mexico | Brazil | Argentina | Chile | Colombia | Peru | Germany | United Kingdom | France | Italy | Spain | Netherlands | Belgium | Switzerland | Sweden | Austria | Denmark | Norway | Poland | Finland | Czech Republic | Hungary | Portugal | Ireland | Greece | Slovakia | Romania | Bulgaria | China | Japan | India | South Korea | Indonesia | Vietnam | Thailand | Malaysia | Philippines | Singapore | Bangladesh | Pakistan | Saudi Arabia | United Arab Emirates | Israel | Turkey | Iran | Qatar | Kuwait | South Africa | Nigeria | Egypt | Algeria | Morocco | Kenya | Ghana | Tunisia | Australia | New Zealand | Russia | Ukraine | Belarus | Kazakhstan | Taiwan | Hong Kong | South Sudan | Uzbekistan | Oman | Jordan | Bahrain | Sri Lanka | Myanmar | Lebanon | Mongolia | Ethiopia | Libya | Angola | Zambia | Zimbabwe | Mozambique | Ivory Coast | Senegal | Uganda | Tanzania | Botswana | Ecuador | Venezuela | Bolivia | Paraguay | Uruguay | Trinidad and Tobago | Panama | Guatemala | Costa Rica | Honduras | El Salvador | Nicaragua | Dominican Republic | Haiti | Cuba